1. Zane -zane na ƙofar da taga

Da farko, da fatan za a sake nazarin zane -zane a hankali, ƙayyade nau'in da adadin windows da ake buƙata daidai da buƙatun salon zane, kuma kammala

An inganta shi da tsayayyen tsayin sa, kuma ana yin sa gwargwadon iri iri da nau'ikan taga daban don haɓaka ƙimar amfani da ƙimar samarwa.

2. Tsarin tsaro

Ma’aikata suna buƙatar yin ado da kyau, sanya samfuran inshorar aiki gwargwadon bukatun aiki, da mai da hankali kan hana haɗarin haɗari. An haramta Pyrotechnics a cikin bitar kuma duk ma'aikatan an hana su shan taba.

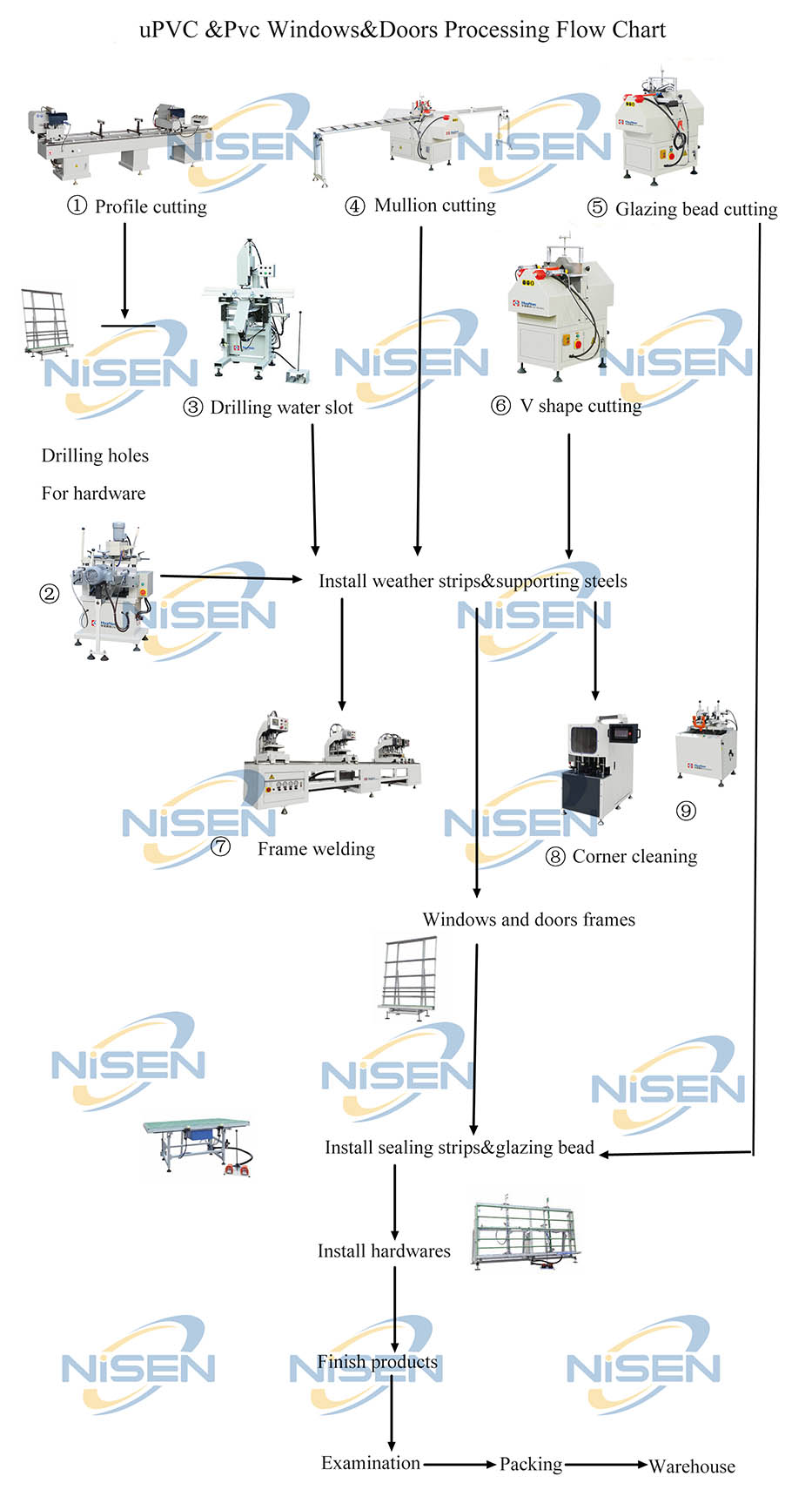

3. Yanke bayanin martaba, milling ramukan magudanar ruwa, makullai

A.Babban bayanin martaba gabaɗaya yana ɗaukar miter sau biyu da aka gani. Bar 2.5mm ~ 3mm a kowane ƙarshen kayan azaman gefe, kuma ƙarƙashin walda. Ya kamata a sarrafa haƙurin abu a cikin 1mm, kuma yakamata a sarrafa haƙurin kusurwa tsakanin digiri 0.5.

B.Yakamata a sarrafa bayanin firam ɗin tare da ramukan magudanar ruwa, kuma nau'in fan ɗin gabaɗaya yakamata a sarrafa shi da ramukan magudanar ruwa da ramukan ma'aunin matsin lamba na iska. Ana buƙatar diamita na ramin magudanar ruwa ya zama 5mm, tsawon 30mm, ramin magudanar ruwa bai kamata a sanya shi cikin rami tare da rufin ƙarfe ba, kuma ba zai iya shiga cikin ramin da rufin ƙarfe ba.

C

4. Majalisar karfafan ƙarfe

Lokacin girman ƙofar da tsarin taga ya fi ko daidai da tsawon da aka ƙayyade, ramin ciki dole ne rufin ƙarfe. Bugu da kari, da hardware taro Dole ne a ƙara rufin ƙarfe a haɗe ƙofofin da windows da aka haɗa da haɗin ƙofofin da tagogi. Kuma gyara. Karfe na sashi a ɓangaren ɗaukar nauyi na haɗin giciye da T-dimbin yawa yakamata ya kasance lokacin da aka ɗora farantin welded bayan an narkar da sashin. Saka karfe gindi a farkon kuma gyara shi bayan walda.

Maƙallan murfin ƙarfe ba zai zama ƙasa da 3 ba, tazara ba za ta fi 300mm ba, kuma nisan daga ƙarshen sashin ƙarfe ba zai fi 100mm ba. Kada a sami ramukan hawa guda ɗaya masu gefe guda uku (gyara guda) na duk taga, tazarar ba za ta fi 500mm ba, kuma nisa daga ƙarshen taga kada ta yi yawa. Na 150 mm. Haɗin T-dimbin yawa yana buƙatar samun ramukan hawa a 150mm a ɓangarorin biyu na tallafin tsakiyar

5. Welding

Lokacin walda, kula da zafin waldi 240-250 ° C, matsin lamba 0.3-0.35MPA, matsa matsa 0.4-0.6MPA, lokacin narkewa 20-30 seconds, lokacin sanyaya 25-30 seconds. Ya kamata a sarrafa haƙurin walda tsakanin 2mm Ciki

6. Share kusurwa, shigar da takalmin roba

A. An raba tsaftar kusurwa zuwa tsabtace hannu da tsabtace injin. Bayan walda, ana iya tsabtace kusurwa bayan mintuna 30 na sanyaya.

B. Frame, fan da gilashin dutsen gilashi, shigar daban -daban na filayen filaye na roba gwargwadon buƙatu. Frame, fan roba tsiri na tsaye;

Tsawon tsinken robar ya kamata ya zama kusan 1% ya fi tsayi don hana tsinken robar ya ragu. Babu sassautawa, tsintsiya, ko tsakiyar bayan girka saman roba

Docking sabon abu

7. Haɗin kayan aiki

An gama ƙofofin filastik-ƙarfe da tagogi daga firam da fan ta kayan aiki. Ka'idar taron kayan aiki shine: isasshen ƙarfi, madaidaicin matsayi, saduwa da ayyuka daban -daban kuma mai sauƙin maye gurbin, yakamata a gyara kayan aikin a cikin nau'in da aka saka akan ƙarfe mai rufi, dole ne a shigar da dunƙule na kayan aikin gaba ɗaya, da matsayin shigarwa na kayan aikin dole ne ya kasance daidai gwargwado.

8. Shigar da gilashi

A ɓangaren da za a shigar da gilashin, saka gilashin gilashin farko, sanya gilashin da aka yanke akan toshe, sannan a wuce gilashin Gilashin gilashin yana manne gilashin da ƙarfi.

9. Kammala samfuran samfuri da dubawa mai inganci

Kafin a yi ƙofofi da tagogi kuma su bar masana'anta, suna buƙatar kunshe -kunshe don hana gurɓatawa. A ƙarƙashin tsarin shigar da sauti, marufi mai gefe ɗaya. Tef ɗin fakitin mai gefe ɗaya ba zai zama ƙasa da maki 3 ba kuma tazara ba za ta fi 600 mm ba. Bayan kunshe, yi alama girman taga a cikin babban matsayi. Bayan an haɗa ƙofofin filastik da tagogi, ana buƙatar tsauraran bincike masu inganci.

A.Binciken bayyanar: Yakamata saman ƙofofi da tagogi su kasance masu santsi, babu kumfa da fasa, rigar launi iri ɗaya, kuma welds ɗin su zama santsi, kuma kada a sami tabo a bayyane. Lahani kamar najasa;

B. Duba girman bayyanar: tsananin sarrafa ingancin ƙofofi da tagogi a cikin halattacciyar karkacewar ma'aunin masana'antar ƙasa;

C. An yi suturar suturar suttura daidai gwargwado tare da saman, gabobin suna da ƙarfi, kuma babu wani sabon abu;

D.Ya kamata a haɗa tsinken sealing da ƙarfi, kuma rata tsakanin kusurwoyi da gindin gindi kada ya fi 1mm, kuma kada su kasance a gefe ɗaya. Yi amfani da madauri biyu ko fiye;

E. An saka kayan haɗin kayan aikin a madaidaicin matsayi, cikakke a cikin yawa, kuma an shigar da su sosai.

Lokacin aikawa: Aug-23-2021